PTFE wire

PTFE wire, also known as Teflon wire, is a specialized type of electrical wire that offers unique properties and benefits in various industries. With its exceptional high temperature resistance, chemical inertness, and low friction coefficient, PTFE wire is favored for applications where reliability and performance are paramount. In this article, we will explore the fundamentals of PTFE wire, its key properties, diverse applications, manufacturing process, considerations for selection, maintenance guidelines, and future technological trends. Understanding the intricacies of PTFE wire can help professionals make informed decisions in choosing the right wiring solution for their specific needs,

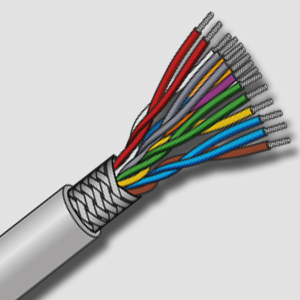

We offer high quality PTFE Wire and cables that are known for strength. These flame resistant PTFE Insulated cables are available in different types. We manufacture these PTFE cables as per the international quality standards. Available in various specifications, the main attributes of our range are given as below:

Temperature range: -100° C to 250° C

Voltage rating: 300 / 500V

Cross - section: 0.14~2.5mm2

History of PTFE Wire

Back in the day, around the 1930s, a clever chemist at DuPont accidentally discovered PTFE while trying to create a new refrigerant. Fast forward to today, PTFE wire is a staple in various industries thanks to its unique qualities.

Properties and Benefits of PTFE Wire

High Temperature Resistance

PTFE wire can take the heat! With its ability to withstand extreme temperatures up to 260°C (that's hotter than a summer pavement), it's a go-to choice for applications where things get steamy.

Chemical Resistance

Splash some chemicals on PTFE wire, and it'll just shrug it off like, "Is that all you got?" Its resistance to a wide range of chemicals makes it a reliable and durable option in challenging environments.

Low Friction Coefficient

If PTFE wire had a dating profile, its headline would be "Smooth Operator." Thanks to its low friction coefficient, this wire glides through spaces with minimal resistance, reducing wear and tear.

Applications of PTFE Wire

Aerospace Industry

In the high-flying world of aerospace, PTFE wire is like the unsung hero silently ensuring smooth communication and power delivery in aircraft systems, where reliability is key.

Medical Devices

When it comes to medical devices, precision and safety are non-negotiable. PTFE wire steps in, offering biocompatibility and reliability for critical applications like diagnostic equipment and surgical tools.

Industrial Machinery

From robotic arms to conveyor systems, industrial machinery relies on PTFE wire to keep operations running smoothly. Its durability and resistance to wear make it a top choice for demanding industrial settings.

Considerations for Choosing PTFE Wire

Temperature Requirements

One of the key considerations when choosing PTFE wire is its temperature resistance. PTFE wire can withstand extreme temperatures, making it suitable for use in high-temperature applications where other types of wire may fail.

Flexibility Needs

PTFE wire offers excellent flexibility, allowing it to bend and flex without losing its structural integrity. This makes it ideal for applications that require frequent movement or bending without compromising the wire's performance.